Stainless Steel Fittings RSS

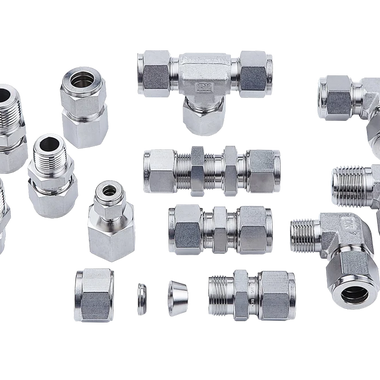

Stainless Steel Twin Ferrule Compression Fittings: A Comprehensive Guide

In the world of piping and fluid transfer, precision and reliability are paramount. Stainless steel twin ferrule compression...

Understanding the Differences Between EPDM, Teflon, and Viton Tri Clover Seals

In the world of industrial sealing, selecting the right material is crucial for ensuring optimal performance and longevity...

What is the Difference Between Grade 304 and 316 Stainless Steel?

Stainless steel comes in many different gradings for different applications and industries. In this article, we will go...

Industries and Uses for Stainless Steel Camlocks

Connecting and disconnecting hoses in industrial settings used to require the use of a many tools. Now, with...

Winemaking and Stainless Steel, the Perfect Pairing?

When you think of wineries, you probably think about the wine and not much else - and we...

BSP vs NPT threads: Understanding the Differences

The location, environment and pressure system can all affect the way a system is sealed. The difference between...

The History of Stainless Steel (Infographic)

Despite its infancy, stainless steel has been revolutionary in the modern world, with a huge impact over the...