Stainless Steel Industrial Valves

Our Stainless Steel BSP Industrial Valves Range

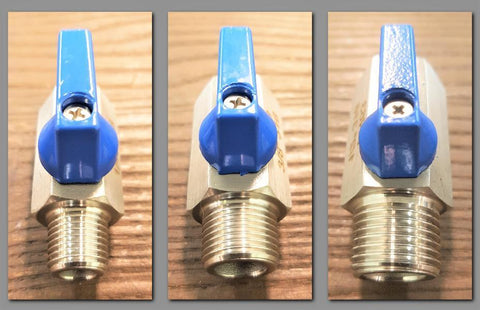

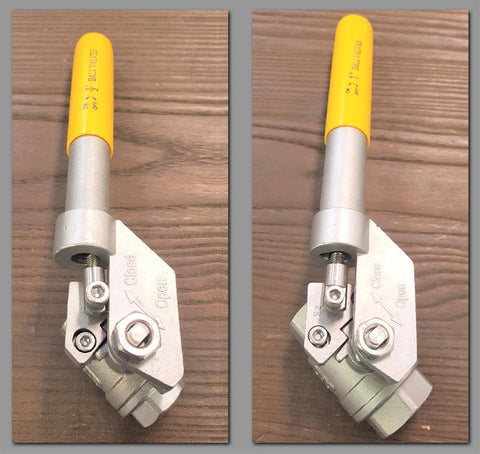

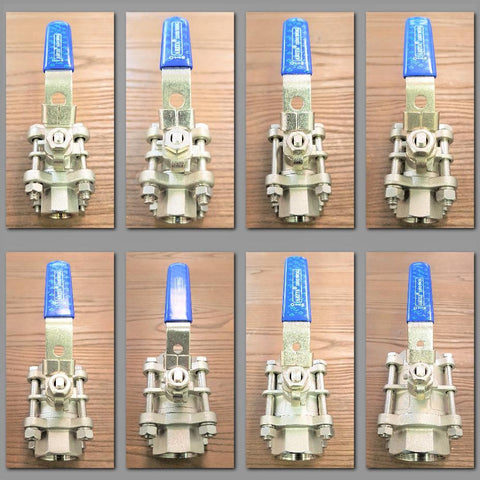

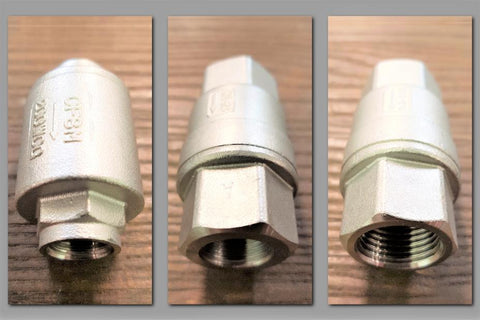

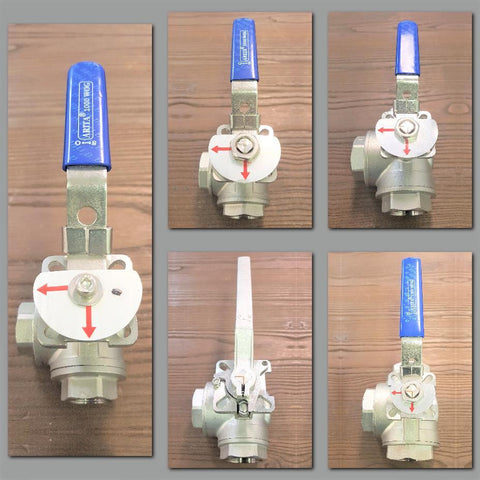

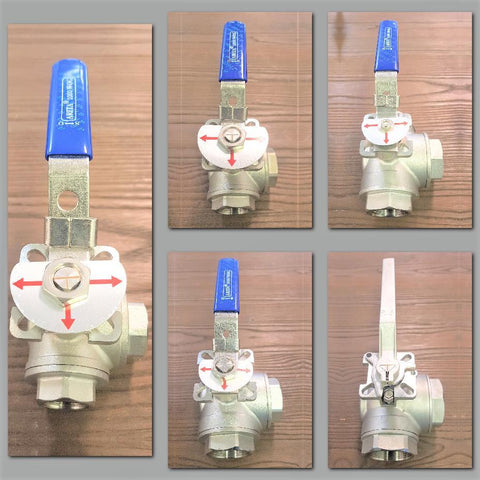

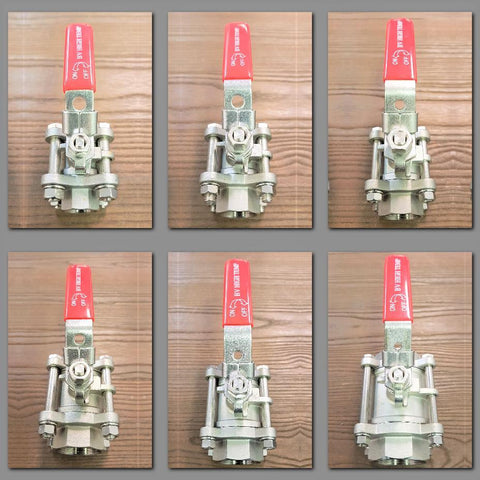

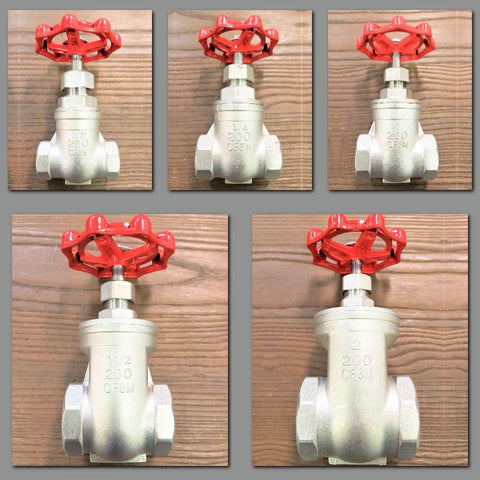

Stattin Stainless stocks a comprehensive range of Grade 316 Stainless Steel BSP Industrial Valves. This collection includes 1 Piece Reduced Bore Ball Valves, 2 and 3 Piece Full Bore Ball Valves, 3 Piece High Temperature Full Bore Ball Valves, Gate Valves, Globe Valves, Swing Check Valves, 2 and 3 Piece Spring Check Valves, Y-Strainers, 2 Piece Dead Man Ball Valves, 3 Way T-Port and L-Port Ball Valves and Mini Ball Valves. We stock sizes between 08 BSP (1/4") and 80 BSP (3").

Industries and Uses for Stainless Steel Industrial Valves

BSP fittings are often referred to as WOG fittings (water, oil, gas fittings). Stainless Steel Industrial BSP Valves are ideal for general purpose applications. They are also normally used in pipe applications but can be used with tube applications using our Tube Toe Nipples. Our Stainless Steel Industrial BSP Valves are long-lasting, hard-wearing and resilient, working to achieve perfect shut off.

Standards and Specifications

ISO 9001:2008

All Valves are manufactured by a ISO Accredited manufacturer, which:

- needs to demonstrate its ability to consistently provide product that meets customer and applicable statutory and regulatory requirements, and

- aims to enhance customer satisfaction through the effective application of the system, including processes for continual improvement of the system and the assurance of conformity to customer and applicable statutory and regulatory requirements.

ASME B16.34 Standard

The ASME valve standard B16.34 “Valves Flanged, Threaded and Welding End” is a valve standard accepted worldwide by end-users, engineering contractors and manufacturers as the fundamental basis for valve design, testing and performance.

API 598 Standard

API 598 covers the inspection, examination, and testing requirements for resilient-seated, nonmetallic-seated, and metal-to-metal-seated gate, glove, plug, ball, check, and butterfly valves. It is relevant to examination and testing by the valve manufacturer, supplementary examinations performed at the valve manufacturer’s plant, and pressure tests performed at either the plant or another mutually agreed-upon facility.

For more information or advice, contact our team of stainless steel experts in Adelaide.