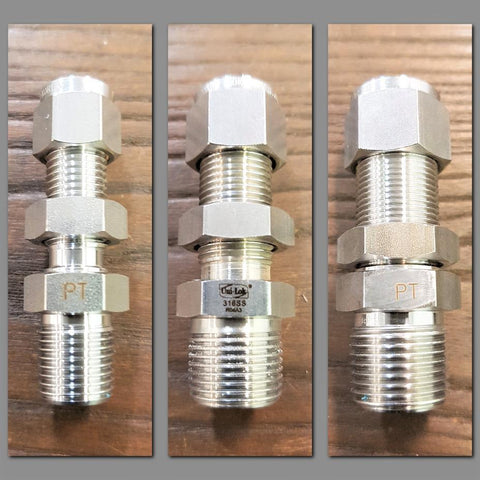

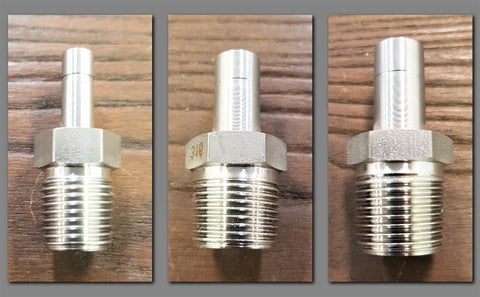

Stainless Steel Twin Ferrule Compression Tube Fittings

Our Grade 316 Stainless Steel Twin Ferrule Compression Tube Fittings Range

Stattin Stainless stocks a comprehensive range of Grade 316 Twin Ferrule Compression Tube Fittings. This collection includes Tube Unions, Tube Union Elbows, Tube Union Tee's, Male Connectors, Male Elbows, Male Bulkhead Connectors, Male adaptors, Plugs, Caps and Ferrule Sets. Sizes range is 3.18mm, 4.76mm, 6.35mm, 9.53mm, 12.7mm, 15.88mm, 19.05mm and 25.4mm.

Stainless Steel Compression Tube Fittings Compatibility

Our Compression Fittings are manufactured in order to be compatible with other brands tube fittings from the beginning of design so that we can be 100% confident of compatible tolerances and hardness with other brands.

Industries and Uses for Stainless Steel Twin Ferrule Compression Tube Fittings

• Oil and Gas

• Pulp and Paper

• Petro-Chemical / Chemical Processing

• Research Laboratories

• Aerospace and Defense

• Chemical processing

• Power Generation

• Cryogenic and Semiconductor

• Shipbuilding and Heavy Industrial

Tube fittings provide leak-free performance for the most demanding applications

Twin Ferrule Compression Tube Fitting Features

Tube fittings provide leak-free performance for the most demanding applications

• Low torque assembly

• Positive leak free seal assembly and reassembly

• Standard materials include 316 stainless steel

• Heat code trace ability for 316 stainless steel

• Size range from 1/8” thru to 1”

• Variety of end connections and patterns.

Installation Instruction

Step 1: Insert the tubing into Tube Fitting's inside. At this moment, make sure that the tubing is completely contact with the shoulder of fittings and then finger-tighten the nut.

Step 2: Before tightening the nut, mark the starting point of turning at the 6 o'clock position.

Step 3: Hold the fitting body safely with a backup wrench and tighten the nut 1-1/4 turns. (pay attention to the mark of starting point of turning, make one revolution and place at 9 o'clock position. Marking the starting point of turning at the 6 o'clock position will let you notice where the starting point is). After 1-1/4 revolution, when the starting point is placed at 9 o'clock position, you can easily confirm and see that Tube Fitting is installed accurately.